"Smalabo TOKYO" Open Corporate Release where you can realistically experience the production robot system from the manufacturing industry

Category: Product service

Release issuance company: TEAM CROSS FA

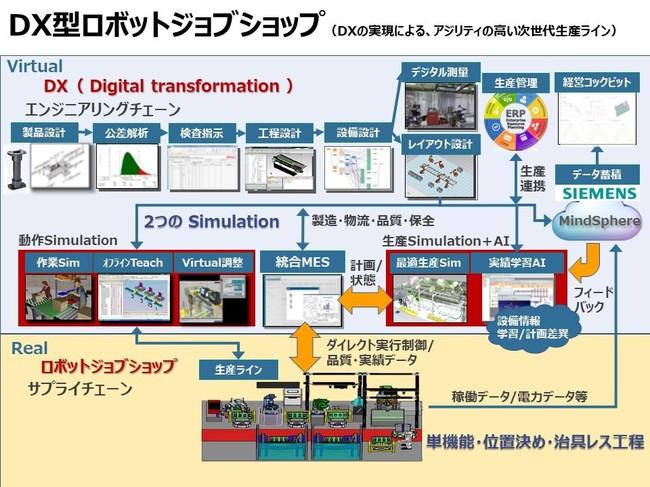

-Enexus the next -generation DX concept line "DX type robot job shop" -The consortium "TEAM CROSS FA" that comprehensively supports the development and implementation of production lines from the manufacturing industryOn September 10, 2020 (Thursday), we will open a showroom, "Smalabo Tokyo), which allows you to realistically experience the production robot system linked to the manufacturing DX.■ Smallab is a showroom where you can realize the various demonstrations that make full use of ROBOT x IoT technology, and realistically experience the production robot system."DX and production lines in the manufacturing industry, which are notable in DX to the actual production robot system and combine" innovative manufacturing "techniques that are applied to actual production robot systems.You can experience it with the actual demonstration.On May 16, 2018, "Sumalabo Koyama" opened in Oyama City, Tochigi Prefecture.More than 10 types of robot systems have been exhibited, and 1200 companies and organizations have been visiting an organization in about two years."Smallabo Tokyo", which will open this time, is a space where you can experience the production robot system / production line that is more linked to DX, such as displaying the next -generation DX concept line "DX type robot job shop".■ About Sumalabo Tokyo Sumalabo Tokyo is a “media” that sends out “management and public institutions” related to manufacturing and logistics industries, “politicians and public institutions” related to the planning and execution of industrial policy, and the latest topics.This is a facility for innovators who are active in realizing DX and production systems in the manufacturing industry.It is located in a place with excellent access to Uchisai -cho, Chiyoda -ku, Tokyo and within walking distance of Kasumigaseki government office.This facility is operated by the consortium "TEAM CROSS FA", which comprehensively supports the development and implementation of production lines to the development and implementation of production lines.FA Products Co., Ltd. (Headquarters: President: Yoshikazu Kida), a secretary of TEAM CROSS FA (Headquarters: Minato -ku, Tokyo: Yoshikazu Kida), and the secretary company office, Inc. Co., Ltd.: Eijo Iino) is responsible for planning, development and operation of demo machines.In the development and operation of demonstrations, the official partner, Hitachi Systems Co., Ltd. (Headquarters: Shinagawa -ku, Tokyo President: Setsuo Shibara), Dentsu International Information Service (Headquarters: Minato -ku, Tokyo: President:We have been cooperating with each company, such as Ryoichi Nawa).■ Solutions Smallab Tokyo, which is exhibited in Sumalabo Tokyo, displays solutions that realize comprehensive solutions for issues such as small quantities production, corresponding to variable varieties, eliminating labor, and creating strong organizations that win in the era of change.Doing.This solution is unprecedented in the manufacturing industry, which is not limited to "improving factory productivity," which maximizes the performance of the entire corporate activity by digitizing the factory and using data accumulation and utilization.。You can experience the next -generation manufacturing industry that can only be realized by Team Cross FA, focusing on the world's leading technical skills in the FA and robot system integrators (robot Sier).■ Next -generation DX concept line "DX type robot job shop" Smallab Tokyo will display the next -generation DX concept line "DX type robot job shop".The "DX -type robot job shop" includes "DX -conated engineering chains", "two Simulation", and "Digital" such as "integrated MES (production, logistics, quality, and conservation)" and the "real" production robot system.Configure digital twin.It is a next -generation DX concept line that is realized by realistic innovative production robot system and digital linkage.The production robot system consists of a job shop called a job shop and a position -determined lesson, and a simple function is configured as a "robot job shop" by combining flexible multi -joint robots and AGV transport.Instead of fixed mass production as in the previous dedicated production line, it is realized as an easy -to -recombinant production line that can be easily recombined and additional for the optimal production at that time corresponding to market changes (varieties, quantity, specifications, etc.).doing.It realizes "optimal production by autonomous control" and "recombination of flexible production according to environmental changes", and is excellent in agility.One of the major features is the use of two Simulation.The first is "Operation Simulation", which realizes a thorough commissioning of production lines on Virtual, such as prior operation verification and workability of product design and process design, and these are real production robots.It works with the system.The second is "Production Simulation" that actually runs the production plan on Virtual to verify the reliable throughput on the production line.At the time of production, in cooperation with the best optimal value derived by production Simulation and integrated MES, the robot job shop is controlled in real time and directly to improve the optimization accuracy such as production throughput and energy efficiency according to the situation change.It will be realized.Achievement data is accumulated in data lake at any time, comparing the performance data and the data at the time of planning, and the AI deepens learning, further improving the optimal operation.For this reason, the more the factory is operated, the more the company will build an "evolution production line" that can enhance the "corporate transformation power (dynamic capability)".In addition, the integration of systems, including our own factory and supply chain, allows production planning and equipment control in consideration of overall optimal, so that resource optimization, including overseas factories, can be realized.Furthermore, simplifying the physical connection between individual processes and devices will make it easier to sort, add, and remove the device, and to recreate functions, so it will be launched, launched, and remodeled.Reduce costs including the time required.In addition, by automatic replacement by the jigless system, automatic production instructions, etc., it automatically tracks the production volume and changes in production items.It will be realized.Team Cross FA will contribute to the creation of new markets through the DX -type robot job shop, as well as solving the manufacturing industry, as well as a system that will sell industrial robots.[Comparison of "DX type robot job shop" and "conventional production line"] DX type robot job shop overall figure of the conventional production line Overall figure ■ Team Cross FA Team Cross Fa Team Cross Fa includes the development and implementation of next -generation production lines.It is a consortium that comprehensively supports DX in the manufacturing industry.The background of the consortium founding is the reality that there is no "consultation" for building a smart factory.Especially in Japan, there are many vendors and companies that have one of the world's leading technologies in each industry and processes, and there are many equipment, equipment manufacturers and specialized trading companies, such as robots, but "Smart is the optimal smart.It was not possible to consult about the factory.TEAM CROSS FA includes all kinds of "industry knowledge", such as automobiles, electronics, foods, materials, and logistics, all "processed experience" such as processing, assembly, inspection, and logistics, and the latest equipment, products, tools.It has the "high technology" cultivated by the accumulation of the achievements of using the system, and as a core with robot SIer, the official partner, the FA Robot SIer in various parts of Japan, the public institutions, and public institutions.In cooperation with the local community, he also cooperates with the Japanese national strategy "Connected Industries".We will contribute to the DX and smart factory of all manufacturing industries.Consortium Name: TEAM CROSS FA (Team Cross Fee) Secretary: ・ FA Products Co., Ltd. (Operating Corporation / Division / Digital Twin Consulting) ・ Robocom Co., Ltd. (Procedure Design / Initiative Design) ・ Office Fee Comes Co., Ltd. (Machine, Machine,Control, software, IT, development contract), Japan Support System Co., Ltd. (Design / parts processing / assembly) ・ Robocom and Feecom Co., Ltd. (Precision parts processing, mass production, assembly), Industrial-X Security Co., Ltd.Security) ・ SAASIS Co., Ltd. (Business System Construction / Consulting) Official Partner: ・ Dentsu International Information Service Co., Ltd. (Cooperation area: Digital Engineering) ・ Hitachi Systems Co., Ltd. (Cooperative area: IT system, maintenance operation) ・ Mitsuiwa Co., Ltd. (Mitsuiwa Co., Ltd.)Cooperation area: Consulting/IT system), Kashima Construction Co., Ltd. (Cooperative area: architectural/engineering), Nikken total sourcing Co., Ltd. (Cooperative area: Technical dispatch/training, maintenance) HP: https: // Connected-Engineering.COM/■ Sumalabo Tokyo Outline Facility Name: Smalabo Tokyo (Smallab Tokyo) Operated by: TEAM CROSS FA (URL: https: // Connected-Engineering.COM/) Location: 〒100-0011 1-1-6 Uchisai-cho, Chiyoda-ku, Tokyo NTT Hibiya Building B1FTEL: 03-6453-6761 (in FA Products Co., Ltd.) Official HP: https: // SmartFactoryLabo.COM/TOKYO/Facility Overview: Applying for a showroom tour that allows you to experience the DX in the manufacturing industry for innovators: Check the notes on the official website and apply from the "Reservation Application Form" Operating hours: 10 weekdays.: 00-18: 00 Closed: Saturday / Sunday / celebration company to PRTIMES Top

情報提供元:PRTIMES本リリースの掲載元:https://prtimes.jp/main/html/rd/p/000000008.000054540.html* Prices, specifications, services, etc. of the products described in the news release are as of the date of announcement.Please note that it may be changed without notice.